Dynamic illustration of 5 kinds of 3d printing metals

Dynamic illustration of 5 kinds of 3d printing metals

Metal 3D printing can be directly used for rapid prototyping of metal parts manufacturing, has wide industrial application prospect, is focus on the development of 3D printing technology at home and abroad, following the principle of 3D printing in current article forward again, metal, polymer, small velocity share NPJ, SLM, SLS, five metal LMD and EBM principle of 3D printing.

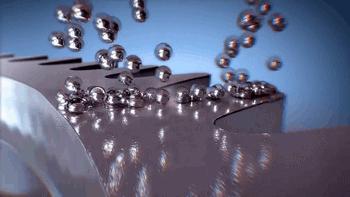

1. NPJ(Nano Particle Jetting)

NPJ technology is the latest metal 3D printing molding technology developed by Israeli company Xjet. Compared with ordinary laser 3D printing molding, NPJ uses nano liquid metal and is deposited in ink-jet way. The printing speed is 5 times faster than ordinary laser printing, and it has excellent precision and surface roughness.

Here is how the Xjet device works:

Granular refinement

Metal particles are distributed in droplets

Droplet jet forming

Liquid discharge

A sintered product

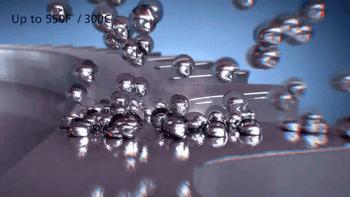

2. SLM(Selective Laser Melting)

SLM, or selective laser melting molding technology, is the most common technology in metal 3D printing molding at present. It uses fine focused light spot to quickly melt preset metal powder and directly obtain any shape and parts with complete metallurgical combination, and the production density can reach more than 99%.

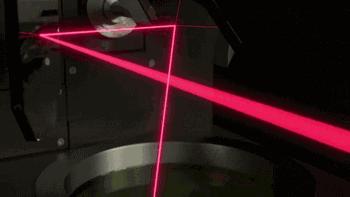

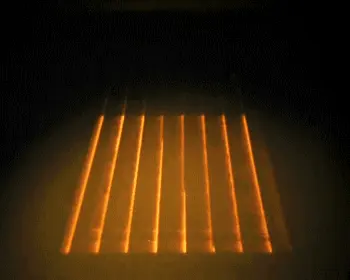

Laser galvanometer system is one of the key technologies of SLM. The following is the working picture of the galvanometer system of SLM Solution:

scanning galvanometer

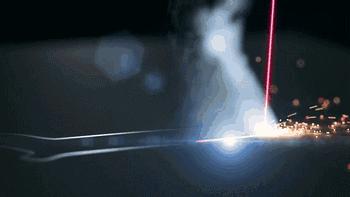

Laser scanning melting

metal powder melting process

In the process of metal 3D printing, support materials need to be printed due to the complexity of the workpiece. After the completion of the workpiece, support should be removed and the surface of the workpiece should be treated。

Take out the parts

Remove the support

Post-polishing

3. SLS(Selective Laser Sintering)

SLS, or selective laser sintering molding technology, is similar to SLM technology, but the difference is that the laser power is different. It is usually used for 3D printing of polymer.

The following is how SLS makes plastic parts:

Model slice

Laser sintering process

The removal of parts

Finished

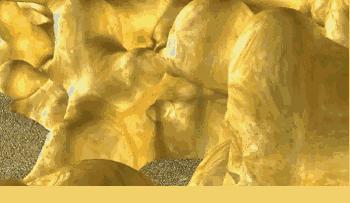

SLS can also be used to make metal or ceramic parts, but the resulting parts have low density and require later densification to be used.

SLS makes metal parts

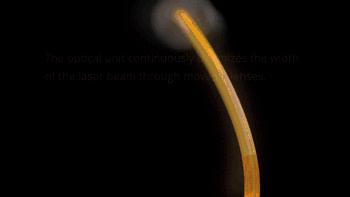

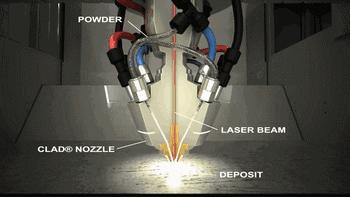

4. LMD(Laser Metal Deposition)

LMD is laser cladding forming technology, which has many names. Different research institutions have independently studied and named it. Common names include LENS, DMD, DLF, LRF and so on.

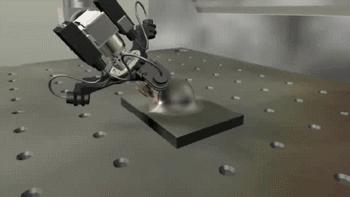

Here's how LENS technology works:

5. EBM(Electron Beam Melting)

EBM, or electron beam melting technology, is very similar to SLM, except that the energy source used in EBM is an electron beam. The output energy of EBM electron beam is usually one order of magnitude larger than the laser output power of SLM, and the scanning speed is much higher than that of SLM. Therefore, in the construction process of EBM, it is necessary to preheat the molding table as a whole to prevent large residual stress caused by excessive temperature in the molding process.

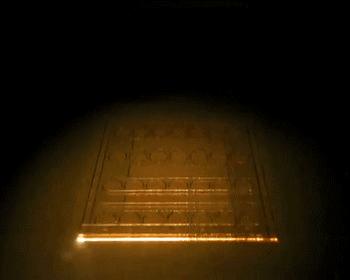

The following is how EBM works:

he preheating

forming process

The change of powder during melting